Reasons You Don't Have to Be a Big Corporation to Start Prototyping

You might wonder whether you should invest in prototyping for your small business. Chances are you think prototyping is for big corporations, and that's where you are wrong. This article will help you learn why you don't have to be a big corporation to start prototyping.

There are several reasons why prototyping is not for big corporations only; to help validate your idea, to get funding, to know the actual cost of production, to stay on track, to adjust the design, to build confidence, to save money, and to improve the integrity of the product.

Keep reading to learn more about how to develop a prototype product.

Reasons You Don't Have to Be a Big Corporation to Start Prototyping

It can take a long time to design and manufacture a new product. Many businesses attempt to minimize this timescale by skipping the prototyping stage and going directly to production.

It might cost you far more time and money if you buy into these ideas. The first phase of getting a product to market is prototyping, which reveals unseen barriers, unforeseen difficulties, and the part's original appearance and feelings. Why would you wait until manufacturing to identify flaws when you might have done it sooner and for a lot less money?

Here are the reasons you don't have to be a big corporation to invest in prototyping;

1. To Validate Your Idea

Even if you have a great idea, investors won't care unless you can prove it works in the real world. Even though market research based on already-available products can be helpful, it is only theoretical unless you can show your product to your target market and get their comments. You can realize this objective through prototypes. You can demonstrate to yourself and investors that there is a market for this product and that it is worth developing.

2. To Get a Funding

Nowadays, it is challenging enough to get investors' interest without having to worry about trying to secure finance. Your chances of getting funding for innovation are essentially nonexistent without a prototype. Investors require proof of concept and like to see working prototypes that they can show to influential decision-makers. Investors will infuse the money necessary to get your product into the stores if your prototype is impressive enough to win them over.

3. Stay on Track

It can be simple to become frustrated in your thoughts while creating something from the start. Scope creep an issue for many product developers since they keep adding features to their original ideas, which drives up R&D expenses and lengthens the development process. You can have a concrete road map to realize your goal with prototypes. You get closer to achieving a goal as you approve each prototype.

4. Adjust the Design

It's not always easy to see a design's flaws on paper or a computer screen. By building a prototype, you can handle a working example of your proposed product and assess which elements are practical and which ones require improvement. This is your opportunity to collect more precise requirements and market input.

5. To Build Confidence

A crucial component of any financial transaction is trust. When your company invests in prototypes, it demonstrates to investors that you have thoroughly studied and investigated your product. Nobody wants to put money into a great idea that doesn't result in a usable product. Prototyping thereby enhances your reputation and boosts investor confidence. Additionally, it promotes consumer confidence that things won't malfunction after being purchased.

6. To Know the True Cost of Production

Engineers may more appropriately estimate the true cost-per-unit of mass-producing their product using prototypes, which gives them insight into the amount of material required.

7. To Save Money

Although it may seem counterintuitive, prototyping can help you save money. By gathering input and detecting problems in the middle of the development cycle rather than at the end, prototyping allows for a more cost-effective development procedure. Costly rebuilding scenarios are avoided as a result. Additionally, you save money by cutting the time required to produce a product by having testing and development departments work together.

8. To Improve The Integrity of the Product

Using a prototype, you can test your product's structural flaws, which could impair functionality.

You can control your costs and immediately fix the issue. Additionally, it emphasizes any design uncertainties and prevents downstream discovery.

How to develop a product prototype

Developing a prototype involves a lot of processes and is not always straightforward. This piece will walk you through easy stages to quickly produce a 3D product prototype ready for your business or clients. Check out these quick techniques to transform the way you come up with ideas:

1. Start Crafting Your Ideas

Since the first question designers ask is, "What should be the ideal design for my product and how would it appear and feel?" they often struggle to develop an innovative idea. Fortunately, new items have emerged which can be quickly prototyped thanks to their simplicity.

Even better than this, these services allow hobbyists or side enterprises to completely alter the scope of their projects. A new product prototype must take into account a variety of aspects. The design selection is influenced by current design trends, client needs, and usability. Significant design considerations include product cost, competitive scenario, and market position.

2. Create a Rough Draft of Your Idea

You should first conduct some product research and develop an idea. Your following action after it is finished would be to make a straightforward depiction of it. Today's 3D printing technology makes it possible to quickly produce new product prototypes that limit waste, save time, and resemble integrated products from the future more closely.

The only method to determine whether a concept is viable is by planning a prototype, even though having an idea in your head may not help you produce a product. Before generating the final product, you can draw or use computer programs to generate the greatest possible representation. You may speed up the process of product optimization and test your product before making a costly investment using a virtual 3D duplicate powered by AI.

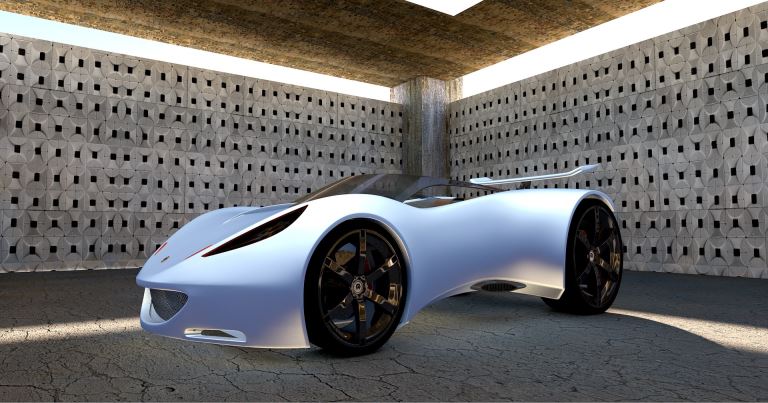

3. Develop a Physical Prototype

The only method to determine whether a concept is viable is by planning a prototype, even though having an idea in your head may not help you produce a product. Before generating the final product, you can draw or use computer programs to generate the greatest possible representation. You may speed up the process of product optimization and test your product before making a costly investment using a virtual 3D duplicate powered by AI.

4. Develop Your Prototype Until It Is Perfect

Your product undergoes several redesigns at this point in the process to match your intended product expectations. To optimize profits, keep abreast of current product design trends and appeal to your target market. Be open to change and aware that your product must undergo specific alterations before going on the market. To achieve the highest quality, never stop trying new ideas because they may continually improve your product.

What are the Characteristics of a Good Prototype?

The primary reason behind creating prototypes is to validate the design of the actual product. Prototyping is sometimes referred to as materialization. The table below shows the typical characteristics found among prototypes.

| Representation |

This is one of the most vital qualities of a prototype. The product should be a good representation of the final product. Therefore, it can be helpful during testing and identifying issues with the final product. Organizations try hard to have a prototype that resembles the design. |

| Improvision |

A quality prototype can be improvised using very minimal effort and time. The prototyping service provider does not have to worry about issues when creating a prototype. In general, a prototype is usually subject to more than one improvisation. |

| Precision |

A good prototype must be exact with the necessary details. Features like size, shape, and material should be apparent- This allows for better response and feedback, enabling the designer to make any changes necessary after receiving the feedback. |

| Functionality | Functionality should be highly considered for a quality prototype. A good prototype must achieve its purpose by performing the actual product's essential functions. |

Conclusion

Not to mention, prototyping results in superior goods. You have numerous opportunities to enhance and perfect your product through prototyping. The ideal combination of designs, materials, components and functionalities can be tested to develop a unique and valuable item.

Through prototyping, you can use the crucial human aspect to uncover hazards and operational problems that cannot duplicate in whatever amount of theoretical testing. The ideal way businesses can verify ideas, test functionality, draw in investors, and save time and money during the development process is by using functional prototypes. Contact Guru solutions to help you with Prototyping services.