Guru Solutions specializes in expert Electronic Breadboard Repair and Circuit Board Repair Service. Get reliable PCB Repair and Electronics Troubleshooting for critical Industrial Electronics Repair. Trust Guru Solutions Repair for quality, efficient service.

Get Started

Get Your Electronics Back Online

Restore Performance and Reliability Today

Don't let malfunctioning breadboards halt your operations. Our expert technicians are ready to diagnose and repair your critical electronic components quickly and efficiently, minimizing costly downtime and restoring full functionality.

Experience the Guru Solutions difference in electronic repair. We employ advanced techniques and quality parts to ensure lasting repairs, extending the life of your valuable equipment. Reach out now to discuss your specific repair needs and get a tailored solution.

Ready to resolve your electronic equipment issues? Take the first step towards dependable performance. Click the button below to connect with our specialists and schedule your Electronic Breadboard Repair Service today.

Restoring Critical Electronic Functionality

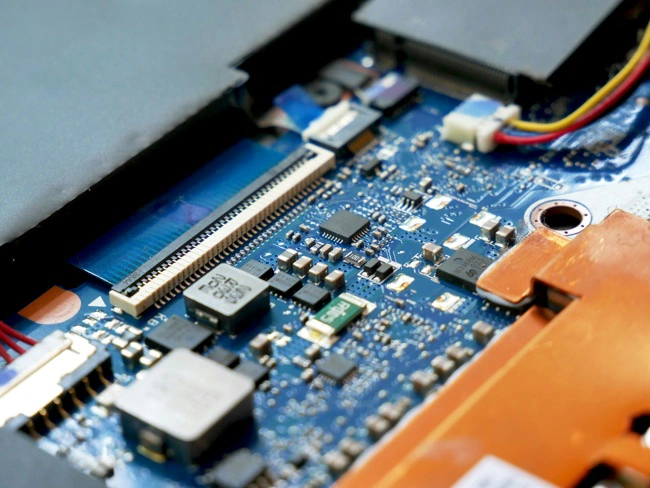

In today's technology-driven world, the operational health of electronic breadboards and circuit boards is paramount. These intricate components are the brains and nervous systems of countless devices and industrial systems, and when they fail, the impact can be significant, causing production halts, data loss, and compromised safety systems. Attempting complex repairs without the proper expertise or tools can often exacerbate the problem, turning a fixable issue into irreparable damage. Reliable service is not merely a convenience; it is a necessity for maintaining operational continuity and efficiency in any sector reliant on sophisticated electronics.

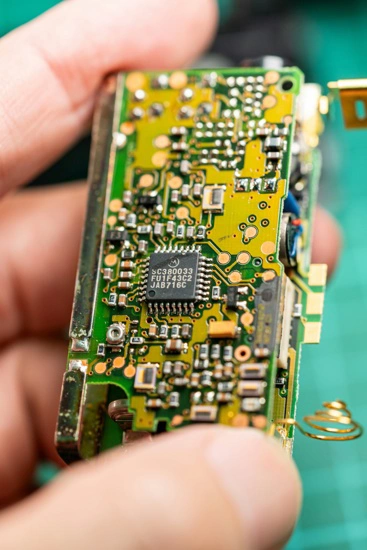

Guru Solutions specializes in precisely this critical area: the expert repair of malfunctioning electronic breadboards and circuit boards. Our service is designed to provide businesses with a reliable alternative to expensive equipment replacement, focusing on meticulous diagnostics and high-precision repair techniques. We understand the complexities inherent in modern electronic systems and possess the technical acumen required to identify and rectify faults at the component level, ensuring that the restored equipment performs as intended, reliably and safely, minimizing the disruption caused by unexpected failures and extending the usable life of your valuable assets.

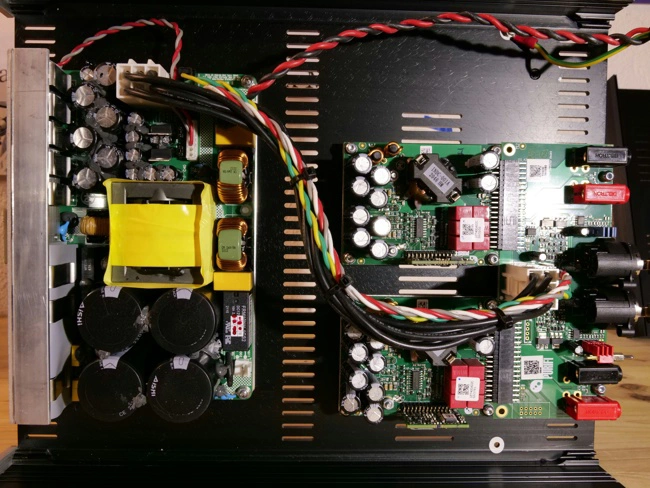

Our approach goes beyond simple troubleshooting; it involves a deep understanding of electronic principles, circuit design, and component behavior under various operational conditions. We utilize specialized equipment to accurately diagnose issues that are often invisible to the naked eye or standard testing tools. This detailed diagnostic phase is crucial for ensuring that the repair addresses the root cause of the malfunction, preventing recurring issues and guaranteeing the longevity of the repair. By choosing Guru Solutions, you are opting for a partner committed to restoring the full functionality of your electronic equipment with unparalleled expertise and a dedication to quality craftsmanship, ensuring your operations remain robust and uninterrupted.

High-Precision Soldering Stations

Our technicians utilize advanced high-precision soldering stations, essential tools enabling the meticulous handling of delicate components and intricate circuit board pathways. These stations provide precise temperature control and fine tips, allowing for the safe and accurate removal and replacement of surface-mount devices (SMDs) and through-hole components without causing thermal damage to the surrounding board material or adjacent parts, ensuring that even the most complex soldering tasks are performed with unparalleled accuracy and maintaining the integrity of sensitive electronic assemblies during the critical repair process effectively.

Advanced Oscilloscopes

We employ state-of-the-art oscilloscopes for in-depth diagnostic analysis of electronic signals. These powerful instruments allow our experts to visualize voltage waveforms over time, identify signal anomalies, noise, distortion, or timing issues that indicate circuit malfunctions, and test the performance of repaired boards under simulated operational conditions, providing crucial insights into circuit behavior and enabling precise Electronics Troubleshooting at a granular level to verify functionality and stability after component replacement or trace repair procedures are completed accurately.

Component Rework Systems

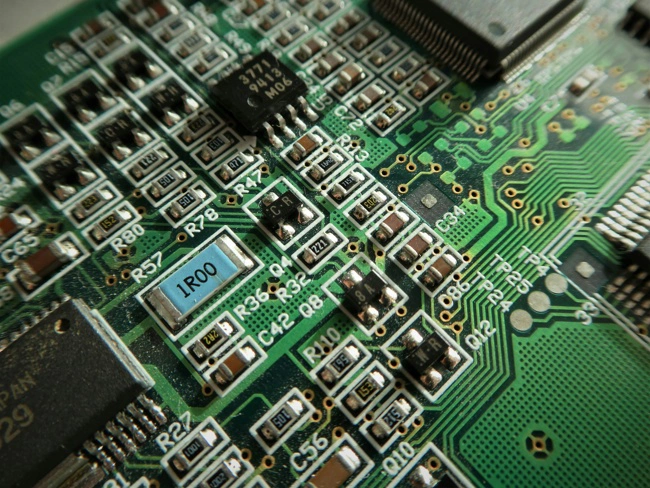

Utilizing specialized component rework systems is fundamental to safely addressing issues with multi-pin and fine-pitch surface-mount components commonly found on modern PCBs. These systems provide controlled heating profiles and precise component placement mechanisms, facilitating the removal and reballing or replacement of complex ICs like BGAs (Ball Grid Arrays) without damaging the board or adjacent components, ensuring that intricate component-level repairs are executed cleanly and reliably, which is essential for restoring functionality to densely populated and highly integrated electronic assemblies with precision.

Digital Multimeters

Fundamental to any electronic repair workbench, high-quality digital multimeters are indispensable tools used extensively by our technicians for various diagnostic and testing tasks. They provide precise measurements of voltage, current, resistance, continuity, and sometimes capacitance or frequency, enabling basic fault isolation, verifying power supply integrity, checking component values, and confirming connectivity within the circuit, serving as a critical first step in diagnosing many electronic issues and providing essential data points throughout the repair process to ensure accurate testing and validation procedures are successfully performed.

Expert Repair for Complex Electronic Systems

Electronic breadboards and circuit boards are becoming increasingly complex, integrating a multitude of components with intricate interconnections within ever-shrinking footprints. Dealing with failures in these sophisticated systems requires a level of expertise that extends beyond basic soldering or component swapping. Industrial electronics, in particular, often utilize proprietary designs and operate in challenging environments, demanding specialized knowledge and robust repair methodologies to restore them to full working order without compromising their integrity or performance specifications under demanding conditions.

At Guru Solutions, our team is comprised of highly experienced technicians who possess extensive knowledge in a wide range of electronic systems, including those found in industrial automation, telecommunications, medical devices, and more. We are equipped to handle repairs on various types of breadboards and printed circuit boards (PCBs), from single-layer designs to complex multi-layer boards with surface-mount technology (SMT) and fine-pitch components.

Our expertise allows us to tackle challenging issues such as damaged traces, shorts, open circuits, and the failure of integrated circuits (ICs) or other critical components that require precise handling and replacement using specialized tools and techniques tailored for delicate electronic repair work.

Our repair process is meticulous and thorough, prioritizing the quality and reliability of the repaired equipment. We don't just fix the obvious problem; we conduct comprehensive testing to identify any potential underlying issues that could lead to future failures. By leveraging our deep understanding of electronic circuits and employing advanced diagnostic equipment, we ensure that the repair is not just a temporary fix but a lasting solution that restores the equipment to optimal performance. This commitment to detailed, expert repair for complex electronic systems sets Guru Solutions apart and provides our clients with the confidence that their valuable equipment is in highly capable hands.

"At Guru Solutions, we understand the vital role reliable electronics play in modern operations. Our Electronic Breadboard Repair Service is built on a foundation of technical expertise and a commitment to restoring critical functionality for our clients, ensuring their success,"

Ready for Reliable Repair?

Get your electronic breadboards and circuit boards repaired quickly and efficiently by the experts at Guru Solutions. Restore performance today with our dependable service.

Reliable Solutions for Downtime Prevention

Unplanned downtime due to electronic equipment failure can be incredibly costly for businesses, leading to lost productivity, missed deadlines, and damage to reputation. While replacing faulty electronic breadboards or circuit boards might seem like a quick solution, it is often an expensive one, especially for specialized or legacy equipment where replacements are hard to source or prohibitively priced. A proactive approach to electronic repair offers a cost-effective and efficient alternative that minimizes disruption and extends the operational life of existing assets, preventing the need for capital-intensive replacements and maintaining business continuity effectively.

Guru Solutions provides a reliable and efficient Electronic Breadboard Repair Service designed to get your critical equipment back in operation swiftly. Our streamlined process, from initial assessment to final testing, is geared towards minimizing turnaround time without compromising the quality of the repair.

We understand the urgency of restoring faulty equipment and work diligently to diagnose and repair issues promptly, ensuring that your operations can resume with minimal delay. Our focus on quick yet precise repairs helps prevent extended periods of downtime, safeguarding your productivity and profitability in dynamic operational environments where every minute counts towards maintaining efficiency and output.

By choosing Guru Solutions for your Circuit Board Repair Service, you are investing in a solution that offers significant advantages over simple replacement. Repairing existing equipment is not only more cost-effective but also often more environmentally friendly, reducing electronic waste.

Our expertise in Industrial Electronics Repair means we can handle a wide variety of equipment, providing a single point of contact for your diverse electronic repair needs. We are committed to providing reliable solutions that restore the functionality of your equipment, prevent future failures through quality workmanship, and ultimately contribute to the seamless and continuous operation of your business, ensuring peace of mind and sustained performance.

Cause

- Power surges or voltage spikes causing component stress.

- Component aging or inherent manufacturing defects leading to failure.

- Physical damage from mishandling, impact, or environmental factors.

- Environmental stress such as excessive heat, moisture, or vibration.

Benefits

- Extended operational lifespan of valuable electronic equipment.

- Significant reduction in costly operational downtime and delays.

- Cost savings compared to the often higher expense of full equipment replacement.

- Improved reliability and performance of repaired electronic assets.

FAQ

Guru Solutions possesses the expertise to repair a wide variety of electronic breadboards and printed circuit boards (PCBs) across numerous industries, including industrial control boards, power supply boards, telecommunication equipment boards, and complex logic boards found in testing and automation systems. Our capabilities extend to both through-hole and surface-mount technology, addressing issues on single-layer, double-layer, and multi-layer boards from various manufacturers and applications, providing comprehensive repair solutions for diverse electronic equipment needs that require specialized attention and technical proficiency to restore full functionality and operational reliability effectively.

The duration of the electronic breadboard repair process at Guru Solutions is dependent on the complexity of the issue, the type of equipment, and the availability of necessary replacement components. While we strive for swift turnaround times to minimize client downtime, our priority is always a thorough and reliable repair. Upon initial assessment, we provide an estimated repair time, and we keep clients informed throughout the process. Expedited services may be available for urgent requirements, ensuring we meet critical operational timelines while maintaining our high standards of repair quality and efficiency for every project.

In most cases, repairing electronic breadboards and circuit boards is significantly more cost-effective than purchasing new replacement equipment, especially for specialized, industrial, or legacy systems. The cost of repair typically represents a fraction of the cost of full replacement, saving your business valuable capital expenditure. Beyond direct cost savings, repair also reduces downtime, avoids the potential expenses associated with integrating new equipment into existing systems, and extends the life of assets, providing a higher return on investment and a more sustainable approach to managing electronic equipment lifecycles effectively and efficiently over time.

Testimonial

Don't Wait - Repair Now

Address your electronic repair needs proactively. Contact Guru Solutions to schedule your Electronic Breadboard Repair Service and minimize costly downtime today.

How to Get it Done

We have a team of experts to help customize your software. Guru Solutions also offers a consultation service if you need advice on the software to use. We offer the best services at fair prices. Give us a call to schedule a meeting; invite us to your office or even home, and we will be there.